Accreditation

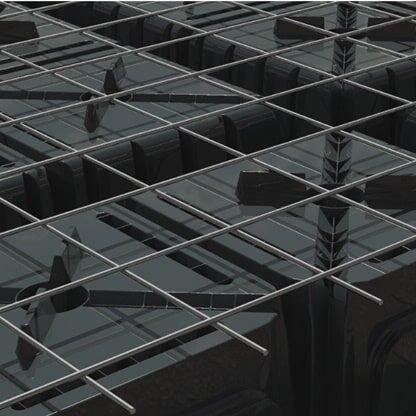

ARC reinforcing steel products are 100% Australian Made and independently certified by ACRS for rebar processing and the manufacture of wire and mesh.

ARC reinforcing mesh and bar products are proudly Australian made and entitled to bear the Australian Made logo. See the quality assurance information below to read more about why you can be confident using ARC reinforcing products.

Sustainability & Environment

At ARC we seek to improve business sustainability by valuing environmental, social and economic considerations.

We strive for continual improvement of environmental performance, the efficient use of resources, and the minimisation or prevention of pollution at world's best practice rates. We also believe in the all-round benefits of diversity amongst our people and strive to be inclusive.

An Environmental Product Declaration (EPD) is a verified and registered document to a recognised international standard and it communicates transparent information about the life-cycle environmental impact of our steel products.

The release of ARC’s EPD increases the multiple ways we can help you gain more points when using national building sustainability rating tools, like Green Star or ISCA. Download a copy here.

ARC formally thanks the Infrastructure Sustainability Council of Australia (ISCA) and the Green Building Council of Australia (GBCA) for recognising our EPD and supporting their value out in the industry.

Green Star is a scheme developed by the Green Building Council of Australia (GBCA) with the purpose of recognising and rewarding environmental leadership within the building industry. ARC steel is proudly Australian made and compliant and our products contribute towards your project achieving its Green Star rating.

Download a copy of our Green Star Confirmation Letter. To learn more visit GBCA or ask your ARC Account Manager.

ARC has been making steel and providing employment for Australians since the company began in 1920. Today we employ more than 700 employees across Australia. We believe that there is strength in diversity, and what sets us apart as individuals makes us stronger as a team. We are currently focused on diversity in three specific areas: diversity of thinking; gender diversity and cultural diversity.

Innovation

We understand the importance of constant innovation to the continued competitiveness of a business. That's why we invest our time and resources into innovative initiatives at all different levels.

Whether it's our R&D partnerships with key researchers, our cost-saving initiatives implemented throughout ARC, our team of project services professionals finding innovative solutions for your particular project or our use of the latest scheduling software, at ARC we are constantly thinking about what comes next.

ARC is the exclusive steel industry partner of the Australia Research Council's Centre for Advanced Manufacturing of Prefabricated Housing. The Research Council is based at the University of Melbourne and has been set up to create a $15 billion prefabricated housing sector in Australia within five years.

The training centre aims to unlock the potential for growth of the prefabricated building industry and has received $4 million in funding from the Australian Research Council and $7 million from industry. The partnership allows ARC to engage in a range of research activities and projects to improve our offering and we're excited to see this result in new value for you as a customer.

Our project services team can help you to find innovative solutions for all kinds of challenging projects. We combine industry experience with the company's strength as Australia's leading manufacturer and supplier of steel reinforcing products. Our project management services directly interface with scheduling, production and delivery, resulting in the streamlined and cost effective delivery of your project.

To find out more about some of our innovative solutions for unique challenges, take a look at some of our projects.

ARC are the only company in the Australian market currently with 3D capability, allowing us to get large amounts of work done more accurately. ScanCAD - we've co-developed with ScanCAD a new automated program which reads your project drawings and completes a large part of the scheduling process to an incredible degree of accuracy.

This program is current industry best practice globally for large projects. CostX - we've also worked with Exactal on the program CostX, a highly automated program that takes your plans, processes them and uploads the number, size and shapes of reinforcing products needed for your project. The result: fast turnaround and pinpoint accuracy for residential projects.